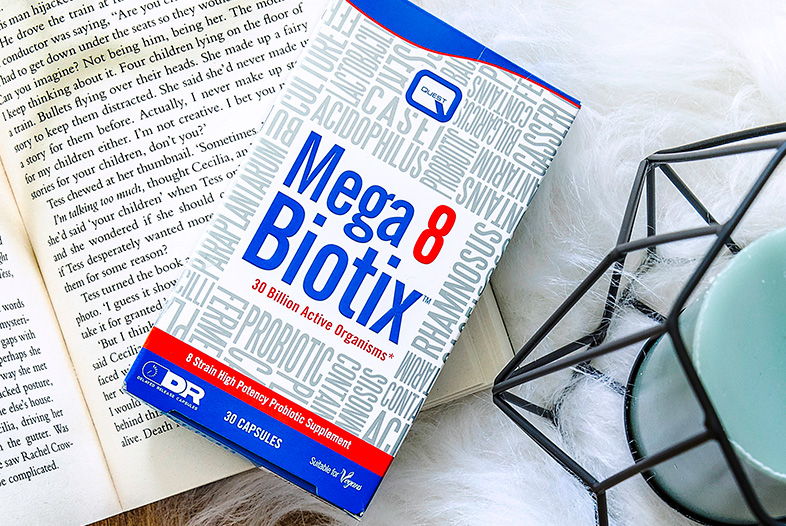

Quest provides contract-manufacturing services for strategically selected partners. We can contract manufacture existing products from our portfolio and also custom develop and manufacture new products, formulations and concepts. All the products are manufactured and quality tested in our GMP facilities.

Contract Manufacturing

Services

Tablet and capsule nutraceutical products in bulk, bottles or blister packs

Powder nutraceutical products in bulk or sachet packs

Liquid nutraceutical products in bulk or bottle packs

Testing and batch release of products

Packaging and pharma serialisation of products

Product development and regulatory support

The Process

We have developed an extensive step-by-step process to which we operate our contract-manufacturing services to deliver the highest levels of quality, support and service levels to our customers.

Define Commercial Relationship

The respective roles and responsibilities of Quest and the partner are defined in writing. Key commercial issues are agreed in advance, including minimum order quantities, pricing, lead-times, product specifications, manufacturing standards, regulatory requirements and after-sales support and service.

Product Selection

The partner selects from the existing Quest product portfolio of 100+ liquid, tablet, sachet and capsule products, including popular established food supplements, specialist innovative nutraceuticals and also traditional herbal remedies.

Product Development

If the partner’s requirements are not met by the existing Quest product portfolio, we develop new bespoke products based on 40+ years of formulation and manufacturing expertise, the latest research on natural molecules and supported by a global network of trusted high-quality raw material suppliers.

Contract Manufacturing Support

Quest also provides ad-hoc manufacturing support such as primary or secondary packaging; encapsulation or tableting of pre-blends; testing and batch release of finished products; and pharma serialisation and barcoding application to finished packs.

Packaging Development

Where label partners require a finished packed product, Quest provides design and regulatory support for the development of impactful and legislative-compliant finished packaging. Quest has 40+ years of experience in packaging development and writing packaging text, including working in different languages.

Regulatory Affairs

Fully comprehensive product dossiers are available from the regulatory a ffairs team, including validation and stability data, where required. The multilingual regulatory a ffairs team have experience in registration of nutraceutical, pharmaceutical and herbal registration in 20+ countries globally.

Production & Final Product Testing

Quest GMP manufacturing capabilities and technologies deliver the highest quality products, which are further guaranteed by comprehensive analytical and microbiology laboratory testing of the finished products.

Logistics & After Sales Service

A dedicated logistics and export team can arrange for airfreight or sea-shipment globally in partnership with our network of trusted logistics agents, ensuring that all the destination paperwork is accurately prepared and transmitted in a timely manner to the consignee.

Quest customer service extends to after the delivery of the goods by providing support for training, product information, product positioning, marketing, retailing and medical detailing.

Product Positioning

All of our products are developed and supported by a clear scientific platform to deliver the impact and health solution for which they are designed. Our products can either be u sed in combination with, as an alternative to, as a follow-on from, or as a precursor to, pharmaceutical products. These four product position strategies apply dfferently and individually product-to-product and can be used to clearly communicate the use and benefits to consumers, retailers and health professionals.

Combination

Selected products may be used in conjunction with conventional treatments for an enhanced solution.

EXAMPLE:

CARNOZIN can be combined with Non-Steroidal Anti-Inflammatory Drugs (NSAIDs) as a gastro-protectant to protect against damage to the stomach lining and ulcers.

Alternative

Selected products may be used as a natural and safe alternative to conventional treatments.

EXAMPLE:

FLAVANON-4 can be used as an alternative to Hormone Replacement Therapy (HRT) in menopausal women to address the symptoms of the menopause safely and naturally.

Follow-on

Selected products may be used as a long-term solution following the completion of a conventional treatment regime.

EXAMPLE:

CRANBIOTIX can be used following a course of antibiotics to stop the reoccurrence of urinary tract infections (UTIs) and prevent the need for repeated antibiotic use.

Protection

Selected products may help to prevent health problems that may require conventional treatment.

EXAMPLE:

Long term CALCIUM supplementation can help maintain bone density and reduce the risk and severity of osteoporosis in post-menopausal women.